Episode 01

Supplying Clean Water

All Around the World

Nitto’s Membrane Business

(High-polymer Separation Membranes)

“We want you to develop support tubes with pressure-tolerant rigidity”

In the early 1970’s Nitto received this request from a client which started our journey

into the membrane business, ahead of other companies, nearly 50 years ago.

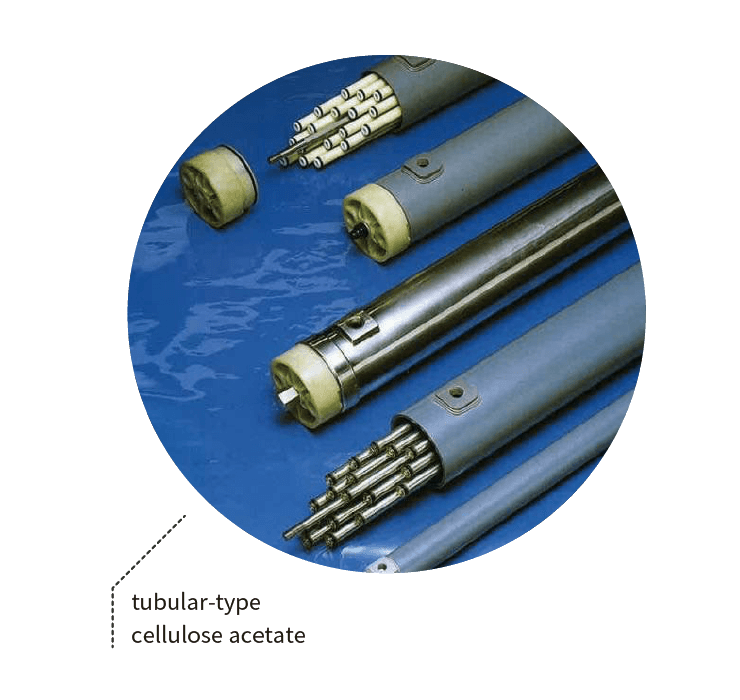

The product began as a polyester FRP tube with microscopic holes, but evolved through the study of tubular-type cellulose acetate.

The reverse osmosis membrane, a high-function membrane that enables sewage water and seawater to be recycled into clean water or industrial water, became the core of our membrane business. With its highly efficient filtering capabilities, this membrane is utilized in various industries including medicine, foodstuff and semiconductors.

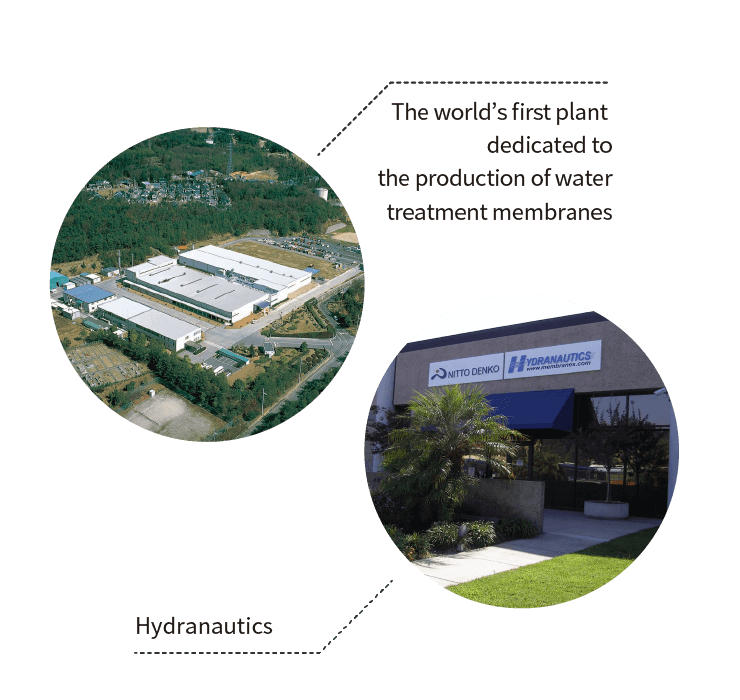

Nitto was able to accelerate the growth of its membrane business, with the establishment of the Shiga plant in 1986. It was the world’s first plant dedicated to the production of water treatment membranes. In 1987 Nitto acquired Hydranautics, a company based in the U.S. - the country where the membrane business was born. This was Nitto’s first acquisition of an overseas enterprise.

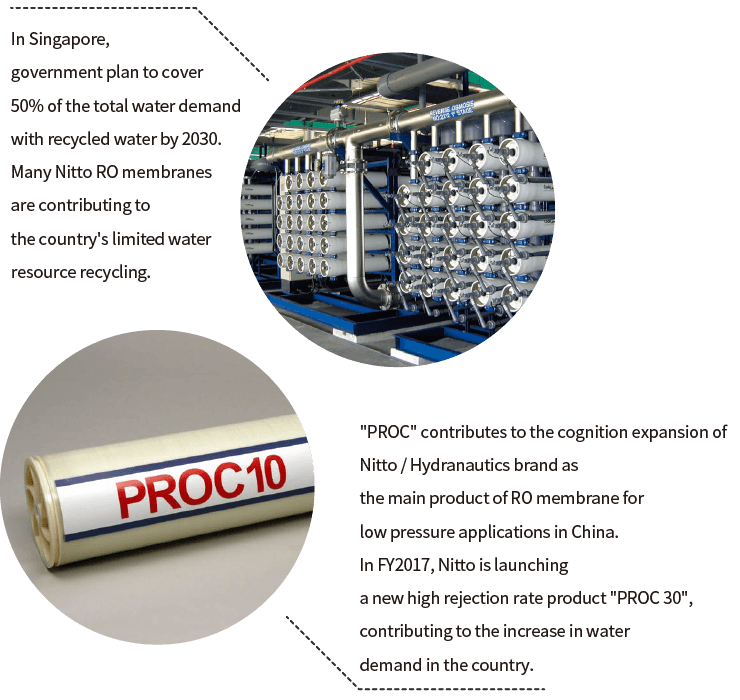

In early 2000 Nitto took part in the NEWater Project, aimed at recycling water in Singapore, where water shortage was a serious issue. Nitto presented the world’s first taint-resistant reverse osmosis membrane. In collaboration with the government of Singapore, Nitto completed the verification test successfully and delivered the product to numerous plants.

In 2002, Nitto began manufacturing membranes in Songjiang, China. The quality of water in China was very poor and the market demanded membranes that would not get clogged with dirt. Nitto delivered a new product that met the market need and grew into the largest manufacturer of reverse osmosis membranes in China. At present, Nitto has business operations in three locations, Japan, the U.S. and China.

“Moments of Change” are

brought by the customers’ voices.

Nitto see changes as opportunities.

Having reached the milestone of our 100th anniversary,

Nitto will continue moving forward with our challenges

to bring satisfaction to our customers.