Episode 02

Nitto that has supported

the evolution of the display industry.

Nitto’s polarizing film business

Flatscreen TVs, personal computers, mobile phones…

Optical films are essential parts of products used in every aspect of our daily lives.

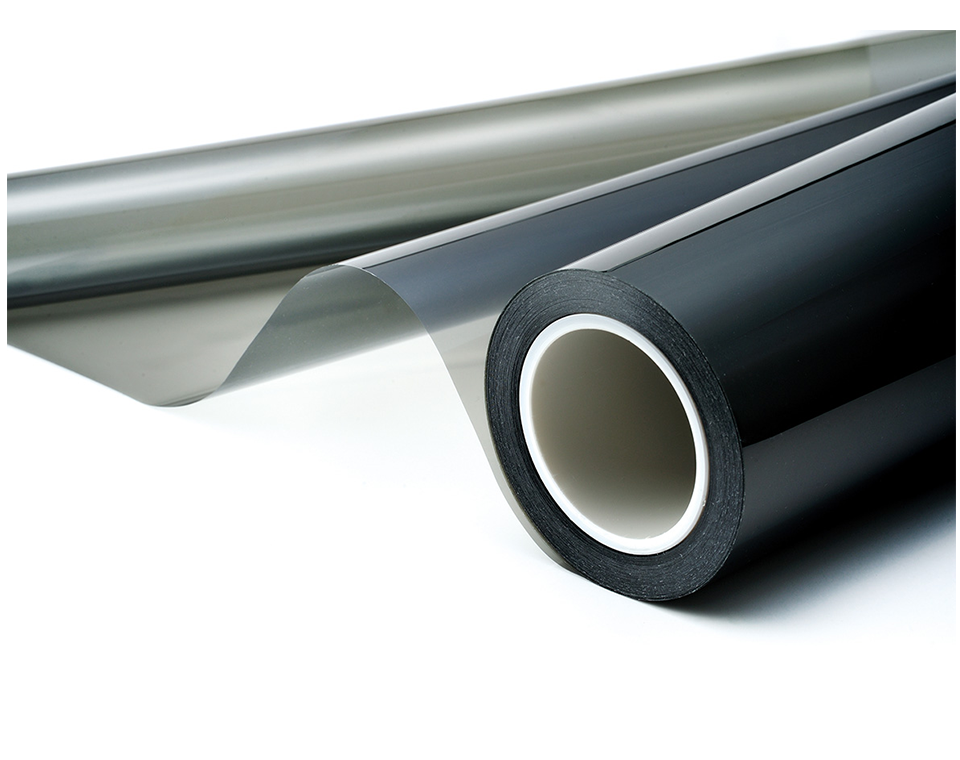

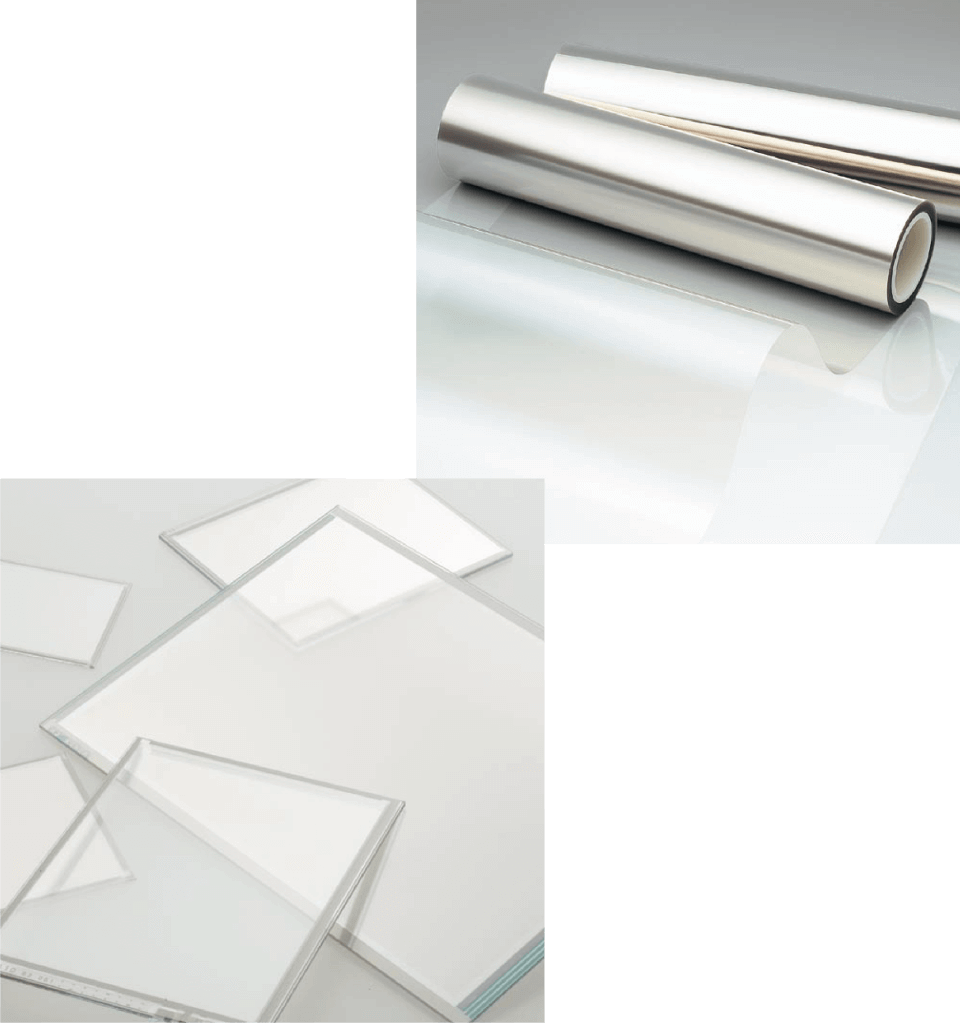

Polarizing films help make LCD imagery brighter and crisper than ever. Transparent conductive film is essential in today’s touch panels.

These films, as well as many other types of optical films, are made with Nitto’s world-class technology.

Polarizing films have a long history. The first invention was made in 1938 by E. H. Land et al. from the Polaroid Corporation. At that time the films were used as base material for anti-glare window shades on trains, ships and polarized sunglasses.

The history of polarizing films at Nitto began in 1975, when we responded to a client’s request to apply paste to polarizing films.

Two years later, in 1977, we were ready with our proprietary polarizing films, being driven by a natural momentum to develop our own product.

Retardation films were developed a little over 10 years later; in 1989.

The product was a solution to the problem of yellow and blue colors appearing on LCD screens in certain display systems due to liquid crystal distortion. The moment of success in developing this product was also the moment Nitto evolved from a mere polarized film manufacturer to an optical film manufacturer.

In 1996 we established the Onomichi Plant. Its extraordinary production capacity is able to respond to the rapid demand increase in the liquid crystal industry. Overcoming difficulties that occurred in the startup process, the plant has grown into our largest production facility in the world.

Nitto’s evolution continued further.

In 1997 we perfected the brightness enhancement film. Light otherwise absorbed by the polarizing films is used to enhance visible brightness when the image is viewed from an angle, contributing to lower power consumption by the display.

This was the moment we evolved further from an optical film manufacturer to a hybrid film manufacturer that provides films with various functions such as brightening and widening viewing angle.

Nowadays, thinner and more flexible displays are in demand, and it is an important challenge for Nitto to make polarizing films even thinner. In such circumstances, Nitto has succeeded in developing a new, innovative ultra-thin polarizer in 2012. A review of conventional processes and materials together with the new manufacturing approaches showed a thickness reduction of approximately 80% and a reduction of shrinkage, which is the cause of panel warping, by approximately 60% compared with standard polarizing films.

Nitto’s transparent conductive film, ELECRYSTA, is being used widely for touch panels on smartphones and tablet devices; items with rapidly increasing demand, along with the shift from use of glass panels to film panels, which are thin, light and unbreakable.

“Moments of Change” are

brought by the customers’ voices.

We see changes as opportunities. Having reached the milestone of our 100th anniversary,

we will continue moving forward with our challenges to bring satisfaction to our customers.