|

Test specimens prepared using a #1 dumbbell die were exposed to each temperature condition. At the end of each time interval, the test pecimens were stretched at the rate of 500mm/min., and the maximum elongation before rupture was measured. Retained elongation was calculated as a percentage of the new specimen’s elongation. Measurement temperature: 80°C |

| Compression[%] | Leakage condition | ||

| No.6800 | No.685 | EE-1000 | |

| 50 | ○ | × | × |

| 60 | ○ | △ | × |

| 70 | ○ | ○ | △ |

| 80 | ○ | ○ | ○ |

○:No leakage after 30min. △:Leakage within 30min. ×:Leakage within

【Test method】

| Compression[%] | Tensile strength[N/cm2] | ||

| No.6800 | No.685 | EE-1000 | |

| Initial | 35 | 10 | 8 |

| Acid(1%H2SO4) | 30 | 10 | 7.5 |

| Alkali(1%NaOH) | 36 | 9.8 | 7.1 |

Each test specimen was placed in a sunshine carbon weather meter and taken out after a set time to measure the elongation by stretching at 500mm/min. Retained elongation was calculated as a percentage of a new specimen’s elongation. |

|

|

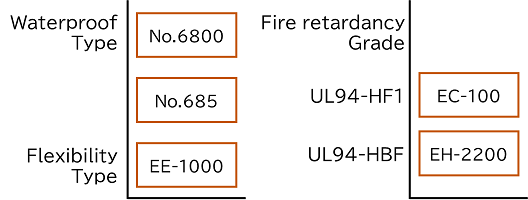

| Foam type | Series name | Product No. | Color | Adhesive | Structure | Features / Applications |

| Closed cell structure | No.6800 Series | No.6800 | Black | Foam only | Automobiles: For sealing around windows and lamps

Houses: For sealing of exterior materials and interior/ exterior walls Foam is low VOC type *VOC: Volatile Organic Compounds |

|

| No.681 | Acrylic adhesive | Baseless | ||||

| No.6801 | Nonwoven fabric base | |||||

| No.6801P | Film base | |||||

| EM-142 | Rubber adhesive | Cotton fabric base | ||||

| Semi-closed

cell structure |

No.685 Series | No.685 | Black | Foam only | For various types of sealing (automobiles, home appliances, housing construction materials)

Foam is low VOC type |

|

| No.686 | Acrylic adhesive | Nonwoven fabric base | ||||

| No.686P | Film base | |||||

| No.687 | Rubber adhesive | Cotton fabric base | ||||

| EE-1000 Series | EE-1000 | Black | Foam only | For various types of sealing (automobiles, home appliances, housing construction materials, etc.)

Foam is low VOC type |

||

| EE-1010 | Acrylic adhesive | Nonwoven fabric base | ||||

| EE-1010P | Film base | |||||

| EE-1040 | Rubber adhesive | Cotton fabric base | ||||

| EC-100 Series

*UL-94 HF-1 certified foam |

EC-100 | Black | Foam only | For various types of sealing (automobiles, home appliances, housing construction materials, etc.)Foam is low VOC type | ||

| EC110 | Acrylic adhesive | Nonwoven fabric base | Foam is flame-retardant, conforms to UL94 HF-1

For sealing of electronics, OA quipment, etc. Foam is low VOC type(Certified thickness follows the UL Yellow Card.) |

|||

| EC-111P | Film base | |||||

| EC140 | Rubber adhesive | Cotton fabric base | ||||

| EH-2200 Series

*UL-94HBF certified foam |

EH-2200 | Black | Foam only | Foam is flame-retardant, conforms to UL94 HBF

For sealing of electronics, OA quipment, etc. Foam is low VOC type(Certified thickness follows the UL Yellow Card.) |

||

| EH-2210 | Acrylic adhesive | Nonwoven fabric base | ||||

|

Door mirrors |

Rear combination lights |

Door trim |

Air conditioners |

Ventilators |

Door speakers |

Sealing material for end rail |

Airproof/waterproof packing between sills and footings |

Sealing material for roof tile (ridge, verge, valley). |

Business Hours(Japan time) 9:00-17:30 Except for Sat, Sun, and Holidays

Global Site