|

Primary oil production from a vertical well typically recovers only about 20 % of the reservoir’s total oil, so for further oil recovery, seawater, heat or carbon dioxide gas is injected into the reservoir. However, sulfate ions present in seawater can cause problems: they form scales that could clog water injection pipes, and a toxic gas is generated from the sulfate-reducing microorganisms, so these sulfate ions must be removed through separation membrane before injection.

Nitto had already introduced NF membrane (NANO-SW) that boasts the highest selectivity of sulfate ions currently available, and has greatly contributed to making offshore oil production more efficiently in the Atlantic Ocean and other seas across the world.

On offshore production platforms, the space is very limited and minimizing the space taken up by water treatment equipment has always been one of the key challenges in the industry. On the other hand, for onshore oil fields in the Middle East, which has recently been attracting more attention, NF membrane with high-pressure resistance is required. This is because the salinity level of the seawater in this region is at around 5% which is relatively higher than that in other regions and nighttime temperature is low, requiring even higher operational pressure, almost double compared to what’s needed for offshore oil field injections.

Nitto developed three new NF products that satisfy specific needs of the oil industry by utilizing our well-established reverse osmosis membrane technologies:

| NANO-SW

Conventional Product | 【Offshore Oil Fields】

NANO-SW-LD MAX New Product | 【Offshore Oil Fields】

NANO-SW ULTRA New Product | 【Onshore Oil Fields】

NANO-SW HP New Product | |

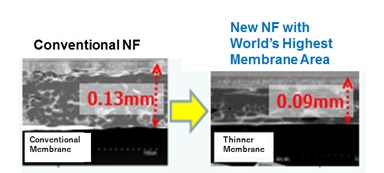

| Membrane Thickness | 0.13mm | 0.09mm | 0.09mm | 0.13mm |

| Membrane Area (ft2 ※1) (8 inch) | 400

(37.2m2) | 440

(40.9m2) | 510

(47.4m2) | 400

(37.2m2) |

| SO42-

Rejection rate (%) | 99.8 | 99.8 | 99.8 | 99.8 |

| Flow (GPD※2) | 11,000

(41.6m3/d) | 12,000

(45.4m3/d) | 13,000

(51.1m3/d) | 11,000

(41.6m3/d) |

| Maximum Operating Pressure (psi) | 600

(4.14MPa) | 600

(4.14MPa) | 600

(4.14MPa) | 1200

(8.28MPa) |

|

For any inquiries about this press release.

Brand Strategy Dept.

Nitto Denko Corporation