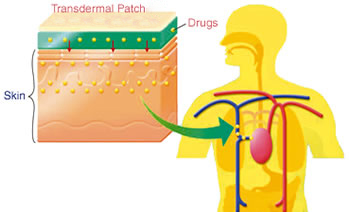

Nitto’s adhesive technology is also used in the medical field. As one of them, we have been developing the patch formulation (transdermal pharmaceuticals) ahead of the world. Patch formulation is a formulation with drug in the adhesive and when the patch is applied to the body, the drug is absorbed from the skin and goes into the blood stream through the capillaries to flow throughout the body. As a result, the drug expresses effect.

|

The mechanism whereby drugs applied to the skin are delivered into the body |

Just including drugs in the adhesive of patch formulation is not enough, and past development of transdermal medication focused on sustained absorption of drugs over a long time. Nitto specializes in blending various compounds into adhesives, but our developers sought to produce formulation that go a step beyond and serve patients better. In other words, we resolved not only to achieve sustained administration but also to develop a product that could deliver the required amount of drugs when needed, as a more evolved transdermal medication.

|

Drug release rate is determined by the complex relationships among the type of adhesive used, the thickness of the adhesive, and the amount and concentration of drug contained.

|

A scene of an experiment that was repeatedly carried out |

To achieve goals, it is necessary to think carefully and to implement the ideas into action, and to repeat this process over and over. Basically, “manufacturing” is tough work that requires much effort and there is nothing stylish about it at all. Because it is so, the pleasure when completed is very special.

At times you may face big hurdles, but you just have to take the initiative and try something else when you get lost. Nothing gets solved sitting at a desk.

“Products leading the world” do not necessarily appear suddenly from some revolutionary idea. This development success teaches developers about the importance of always having a mindset of “you'll never know unless you try.”

Business Hours(Taiwan time)

8:30-17:30 (Except for Sat, Sun, and Holidays)