Le Groupe Nitto inscrit l’ESG (Environnemental, Social et Gouvernance) au cœur de sa gestion, visant à résoudre simultanément les problèmes sociaux et à créer de la valeur économique. Nous devons résoudre la question du changement climatique, en particulier le réchauffement climatique, en tant que problème commun à toute l’humanité, pour transmettre la planète abondante aux générations futures.

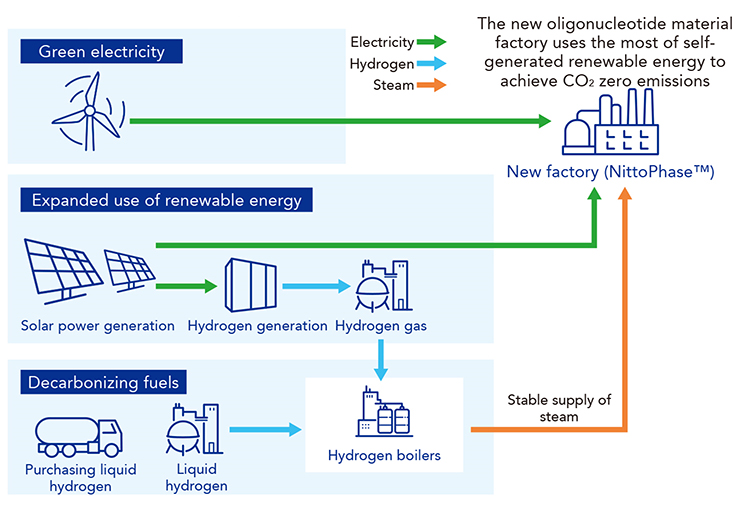

La nouvelle usine de l’usine de Tohoku commencera ses opérations pour diriger la décarbonisation du Groupe Nitto en tant qu’usine avec zéro émission de CO2 qui n’utilise pas de combustibles fossiles. Plus précisément, les panneaux solaires seront doublés pour atteindre 1 500 kW, et l’électricité excédentaire générée les jours fériés sera utilisée pour produire de l’hydrogène vert, qui sera stocké dans des réservoirs d’hydrogène. Des chaudières à vapeur alimentées par de l’hydrogène gazeux ont été introduites à la place des chaudières à vapeur conventionnelles utilisant des combustibles fossiles. Il s’agit de la première initiative au Japon à utiliser une grande quantité d’hydrogène liquéfié pour produire de l’hydrogène gazeux et faire fonctionner des chaudières à vapeur.

Usine à zéro émission de CO2 de l’usine de Tohoku, qui utilise de l’hydrogène |

Le Groupe Nitto accélérera ses activités pour réaliser une société décarbonée grâce à l’utilisation de la technologie environnementale et de l’énergie verte qui font le meilleur usage de l’énergie générée.

À propos de l’usine de Tohoku

L’usine de Tohoku a démarré ses activités en mars 1977 et fabrique des produits thérapeutiques à base d’oligonucléotides tels que NittoPhase™*2, des produits pharmaceutiques et des matériaux d’hygiène médicale. La nouvelle usine, qui a été achevée dans l’usine de Tohoku, est la dernière usine de produits thérapeutiques à base d’oligonucléotides dans le but d’augmenter la production de NittoPhase™ sous le concept d’une « usine respectueuse de l’environnement et de l’homme », garantissant une qualité et une sécurité élevées tout en atteignant une productivité élevée et en offrant une extensibilité future. En termes d’initiatives environnementales, l’usine s’efforce d’atteindre zéro émission de CO2 en convertissant l’électricité excédentaire de la production d’énergie solaire en hydrogène et en installant des chaudières à hydrogène. En outre, il s’agit de réduire la consommation de solvants en recyclant les solvants organiques. En augmentant la capacité de production de NittoPhase™ à l’usine de Tohoku, Nitto soutiendra l’industrie thérapeutique à croissance rapide des oligonucléotides et contribuera à la santé des personnes et à une société sécurisée.

■ Usine de Nitto Denko Corporation Tohoku

Référence :

For any inquiries about this press release.