Nitto’s industrial tapes are manufactured with 100% in-house designed and created adhesives. Solvents like toluene or ethyl-acetate are important raw materials for Nitto’s adhesives. Traditionally, tapes based on these solvents are not affected by humidity, which makes them stable and reliable products for any type of application.

The basic concept of an adhesive is that all ingredients are dissolved in the solvent. The wet adhesive is applied (= coating process) onto a non-woven, plastic or paper carrier. The wet adhesive is then dried in an oven, allowing the solvent to evaporate which results in a dry pressure-sensitive adhesive tape. This means that when the tape is applied with mild pressure, it gives a 100% secure adhesion onto a dry and dust-free surface.

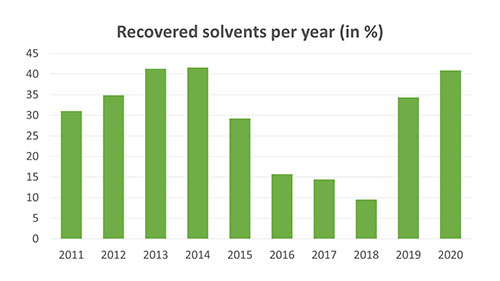

The evaporated solvent is captured during manufacturing and can be processed in two ways through solvent incineration or solvent recovery.

The evaporated solvent is captured and guided to a regenerative thermal oxidizer. The energy in the form of heat created in this process is re-used to heat thermal oil used in the manufacturing process. Nitto Belgium has been using this technique since 1989.

|

|

The drop in recovered solvents from 2015 to 2018 is related to the introduction of the environmentally friendlier solvent ethyl-acetate. The solvent recovery installation was not capable of recovering this solvent at that time. After an extensive upgrade, the recovery percentage increased again to 35% in 2019 and 40% in 2020.

Nitto Belgium is currently investigating how to increase the recovery percentage of its solvents. Although the incineration process is converting solvents into energy in the form of heat, it is still a source of CO2 emissions. The company has set a target of reducing its CO2 emissions by 38% in 2022 and by 55% in 2030 (based on the CO2 emissions of 2018).

Nitto Belgium has succeeded in creating the first emulsion based adhesives (using water instead of toluene or ethyl-acetate), which are offering similar stability and performance as solvent based adhesives.

It is the intention of Nitto Belgium to replace all solvent based adhesives by emulsion based adhesives in the future.